| Technical data | 4S/450 | 4S/600 |

|---|---|---|

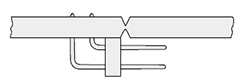

| Separation type | Component side: circular blade Solder side: linear blade | |

| Operation | optimized motor driven | |

| Separation speed | 300/500 mm/s switchable | |

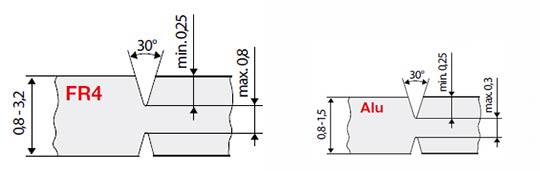

| Material | FR4, aluminum | |

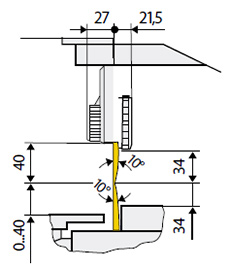

| Height of components | Solder and component sides up to 34 mm | |

| Continuously adjustable separation length | up to 450 mm | up to 600 mm |

| Width of supporting table | 200 mm | |

| Programming | ||

| Start | Traverse to starting position | |

| Programs | 9 | |

| Separation steps | 1-5 | |

| Blade distance | 0.9 mm up to 0.05 mm | |

| Key switch button | Release program selection | |

| Cutting performance display | up to 99 km | |

| DEL | Reset step count | |

| Power switch | ON / OFF | |

| Foot switch | START Operation | |

| Safety switch | Emergency stop | |

| Voltage | 100–240 V~ 50/60 Hz, PFC | |

| Emission sound pressure level | LpA < 70 dB (A) | |

| Temperature/humidity: operation Temperature/humidity: storage Temperature/humidity: transport | +5–40°C/10–85% not condensing 0–60°C/20–80% not condensing -25–60°C/20–80% not condensing | |

| Weight | 38 kg | 46 kg |

| Height x Depth | 434 x 425 mm | |

| Width | 702 mm | 852 mm |

| Approvals | CE, FCC class A | |

| Maximum height of components next to the groove. |  | |

| Increase in external dimensions after separation. | typical 0.2 mm | |

The pre-scored groove can be interrupted by cutouts. | ||

| If components project above the groove, the linear blade needs to be cut out. In such a case contact us. |  | |