| Machine Configuration | |

| Transport height Max. transport width Interface Transfer direction Operating side Fixed rail | 850 mm ± 50 mm 460 mm SMEMA, Siemens from left to right Front of the machine Front of the machine |

| Panel Dimensions | |

| Panel length Panel width Panel thickness Component clearance Panel weight Max. weight | 100 to 460 mm 50 to 460 mm 0.3 to 3 mm ± 40 mm max. 2 kg max. 20 kg |

| Installation Requirements | |

| Power supply Power supply system Power consumption Air supply Air consumption | 230 V / 115 V, 50 / 60 Hz, ± 10% L1 + N + PE 0,5 kW 6 bar 10 Nl/min |

| Machine Description | |

| Length x Width x Height Netto weight Noise Level | 1130 x 1375 x 1535 mm < 365 kg < 75 dB |

| Buffer Description | |

| Buffer spacing Buffer capacity | 30 mm 10 slots |

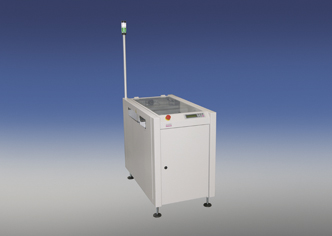

EGO Dynamic FPS 10B SPI / Closed process buffer within production lines

Available on backorder

The buffer station FPS 10B SPI is used to store PCB´s which have been tested as „good“ or bad“.

Bad PCB´s will be always buffered and are only unloaded on request from the operator. On demand, the good PCB´s will be automatically buffered from the downstream system.

The machine is characterized by its short cycle times and can be used behind a solder paste inspection system (SPI) to compensate for process-related downtimes. The FPS 10B SPI works according to the FIFO (First In / First Out) principle and can store up to 10 PCB´s. The buffer itself consists of multiple closed conveyor segments built on top of each other which can also easily process PCBs with sideward cut-outs.

Features

Touch Display with graphical user interface

Product parameters can be changed during running operation

Product memory function

Operating modes and settings:

FIFO

Pass-through

Buffer „Bad“ PCBs

Buffer „Bad“/“Good“ PCBs

Buffer slots can be enabled/disabled

Average Cycle time < 15s. with FIFO

Electric width adjust

Special communication to SPI systems (RS 232)