| Machine Configuration | |

| Transport height Max. transport width Interface Transfer direction Operating side Fixed rail | 850 mm ± 50 mm 460 mm SMEMA, Siemens from left to right Front of the machine Front of the machine |

| Panel Dimensions | |

| Panel length Panel width Panel thickness Component clearance Panel weight | 70 to 460 mm 50 to 460 mm 0.5 to 4.5 mm + 12 mm / – 40 mm max. 3 kg |

| Installation Requirements | |

| Power supply Power supply system Power consumption Air supply Air consumption | 230 V / 115 V, 50 / 60 Hz, ± 10% L1 + N + PE 0,75 kW 6 bar 10 Nl/min |

| Machine Description | |

| Length x Width x Height Netto weight Noise Level | 1295 + 2x Magazine length x 1155 x 1770 mm 570 kg < 75 dB |

| Magazine Size | |

| Magazine length Magazine width Magazine heigth Slot spacing Buffer spacing Single magazine weight | 535 mm 530 mm 568 mm 5 – 20 mm 1 – 50 Slots max. 30 kg |

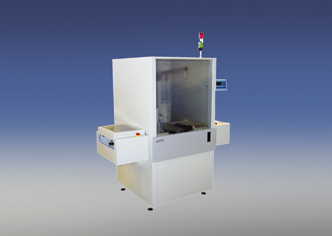

VEGO Dynamic MPS 100 / Closed process buffer with two PCB magazines

Available on backorder

The buffer combines the functionality of magazine loader and unloader in one unit. Incoming PCB’s can be stored in a magazine and on demand from a following unit they can be pushed out and transferred. The unit is equipped with a conveyer underneath the magazine for pass-through mode. This unit is also equipped with two magazines and two magazine axles.

This allows a high buffer capacity, three sorting possibilities and also the possibility of a separate use for each magazine. For example the unit can be used with the first magazine as a storage unit and the second magazine as a loading unit, both functioning independently of each other.

Features

Changeable magazine

Pass- through conveyor underneath the magazine platform

Error loop

Electric width adjustment

Variable operating modes:

Pass-through

Load

Unload

Input transfer

Output transfer

LIFO

FIFO

Sorting

Cooling