Simple BGA rework procedure

BGA rework poses the problem of accessing hidden interconnects in a high density environment. Consequently, it requires a station that is able to access the hidden joints without affecting neighbouring components.A station that is safe, gentle, adaptable and, above all, simple to operate.

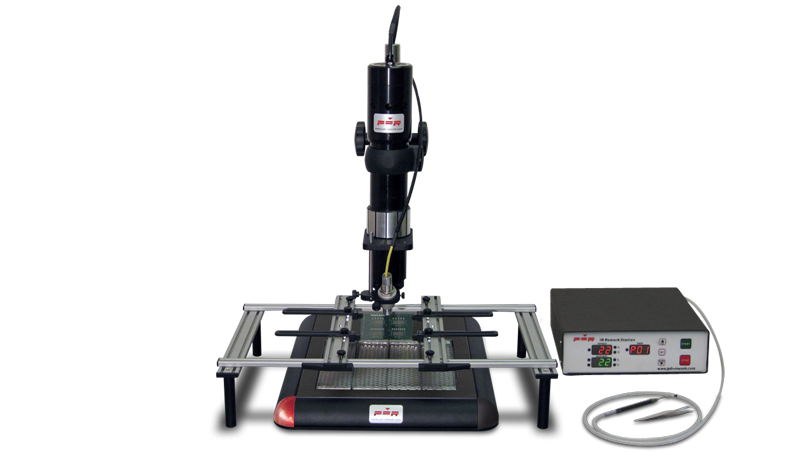

The IR-C3 Chipmate is such a station. It is so easy to operate that technicians are able to instantly achieve excellent process control for BGA/SMT rework without the complexities and frustrations normally associated with ‘high end’ rework stations.

The IR-C3’s standard features, with the use of simple aids, operators can simply pick up the BGA, align it, place it into fluxed pads and reflow with the station’s accurate closed-loop component temperature control.

Advanced Features:

Advanced Focused IR component heating

150W, lens based Focused IR heating with adjustable image system

Quartz IR PCB preheating

2000W, two zone (240mm x 240mm heating area)

Precision Component Pick and Placement

Professional vacuum placement system

Precision PCB Handling

Portable Benchtop PCB workholder

Component Temperature Sensing

Standard non-contact IR temperature sensor

PCB Temperature Sensing

K-type wire thermocouple

Advanced Thermal Process Control

Digital based auto profile thermal control

Please Visit Manufacturers Website For More Information