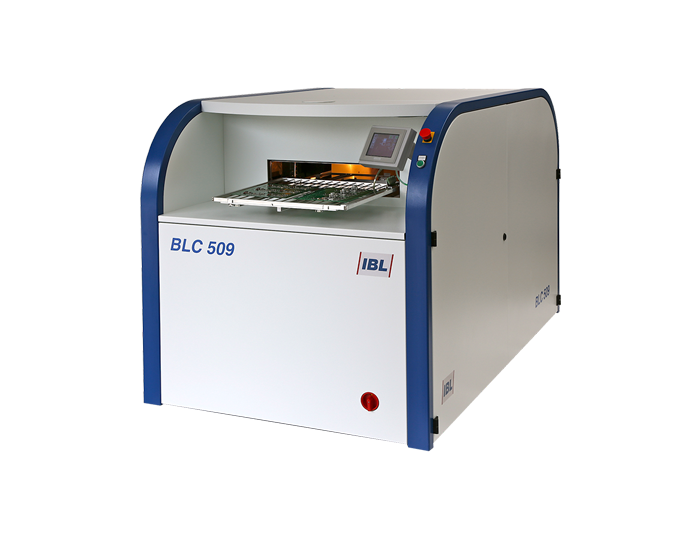

The Machine The SLC/BLC reflow vapor phase soldering systems (available as batch or inline) are perfect for medium to high volume production. The machines offer highest quality performances with smallest footprints. Many patented features are available and provide a wide range of flexibility

SLC/BLC vapor phase oven

Available on backorder

Powerful unit for highest demands

Different machine types with carrier sizes from 300 x 340 x 80 mm up to 840 x 540 x 80 mm

Small footprint

Low energy and fluid consumption with 2-chamber design and integrated heat exchanger

Highest precision and process quality with patented Soft Vapor Temperature Control (SVTC)

Easy one step profile set-up with Intelligent profiling system (IPS)

Wide variety of adjustable solder profiles

Lead-free and leaded soldering on one machine with one fluid

Live temperature monitoring with IBL Software (VP- Control) without profiler

Traceability and documentation with IBL Software (VP-Control) optionally with barcode function

Low maintenance due to Cool Handling (all moving parts outside process chamber)

Maintenance-free transport system (patented)

Integrated automatic fluid filter system

Observation window into process chamber

Optional patented Rapid Cooling System (RCS) for heat reduction of sensitive parts