| Type 1 | Type 2 | |||

| Machine Configuration | Straight | 90 ° backside (RS) | 90 ° frontside (VS) | Straight |

| Transport height Max. transport width Interface Transfer direction Operating side Fixed rail | 850 mm ± 50 mm 260 mm SMEMA, Siemens From left to right Front of the machine Front of the machine | 850 mm ± 50 mm 260 mm SMEMA, Siemens From left to right Front of the machine Front of the machine | 850 mm ± 50 mm 260 mm SMEMA, Siemens From left to right Front of the machine Front of the machine | 850 mm ± 50 mm 460 mm SMEMA, Siemens From left to right Front of the machine Front of the machine |

| Panel Dimensions | ||||

| Panel length Panel width Panel thickness Component clearance Panel weight | 70 to 400 mm 50 to 260 mm 0.7 to 4.5 mm ± 40 mm to 3 kg | 70 to 350 mm 50 to 260 mm 0.7 to 4.5 mm ± 40 mm to 3 kg | 70 to 350 mm 50 to 260 mm 0.7 to 4.5 mm ± 40 mm to 3 kg | 70 to 460 mm 50 to 460 mm 0.7 to 4.5 mm ± 40 mm to 3 kg |

| Installation Requirements | ||||

| Power supply

Power supply system Power consumption Air supply Air consumption | 230 V / 115 V, 50 / 60 Hz, ± 10% L1 + N + PE 0,5 kW 6 bar 5 Nl/min | 230 V / 115 V, 50 / 60 Hz, ± 10% L1 + N + PE 0,5 kW 6 bar 5 Nl/min | 230 V / 115 V, 50 / 60 Hz, ± 10% L1 + N + PE 0,5 kW 6 bar 5 Nl/min | 230 V / 115 V, 50 / 60 Hz, ± 10% L1 + N + PE 0,5 kW 6 bar 5 Nl/min |

| Machine Description | ||||

| Length x Width x Height Netto weight Noise Level | 1965 x 860 x 1820 mm 350 kg < 75 dB | 1105 x 1820 x 1820 mm 380 kg < 75 dB | 1105 x 1820 x 1820 mm 380 kg < 75 dB | 2630 x 930 x 1820 mm 400 kg < 75 dB |

| Magazine Size | ||||

| Magazine length Magazine width Magazine heigth Slot spacing Buffer spacing Magazine buffer input conveyor Magazine buffer output conveyor | 400 mm 320 mm 568 mm 5-20 mm 1-50 Slots 2 2 | 355 mm 320 mm 568 mm 5-20 mm 1-50 Slots 2 2 | 355 mm 320 mm 568 mm 5-20 mm 1-50 Slots 2 2 | 535 mm 535 mm 568 mm 5-20 mm 1-50 Slots 3 3 |

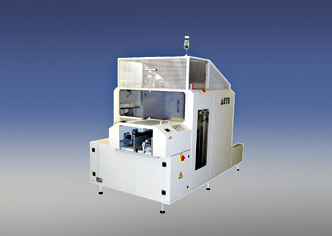

VEGO Dynamic AMS 04 / Magazine loader with magazine buffer and automatic magazine change

Available on backorder

The line Unloader AMS 04 provides an automatic magazine exchange for continnous loading into a magazine. The unit consists of a loading and an unloading conveyor for magazines, a lifting axle with a magazine platform, a buffer conveyor and an electrically driven pusher. The loading conveyor for the magazines is situated directly above the unloading conveyor.

The magazines are transported over the upper (loading) conveyor onto the magazine platform. The pusher slides the PCB’s from the conveyor into the magazine. The full magazine is then transported over the lower (unloading) conveyor and stored until manual removal.

Features

Automatic magazine change with magazine clamps at the top and the bottom

Loading and unloading conveyers situated directly one above the other

PCB buffer conveyor with el. pusher and cover

Touchscreen color display

LED towerlight and buzzer