| Machine Configuration | |

| Transport height Max. transport width Interface Transfer direction Operating side Fixed rail | 850 mm ± 50 mm 460 mm SMEMA, Siemens from left to right Front of the machine Front of the machine |

| Panel Dimensions | |

| Panel length Panel width Panel thickness Component clearance (by-pass) Panel weight Max. stack height Max. batch weight Edge support by-pass Edge support stack | 70 to 460 mm 85 to 460 mm 0.5 to 4.5 mm ± 40 mm to 3 kg 6 x 60 mm 8 kg each batch 3 mm 8 mm |

| Installation Requirements | |

| Power supply Power supply system Power consumption Air supply Air consumption | 230 V / 115 V, 50 / 60 Hz, ± 10% L1 + N + PE 0,5 kW 6 bar 10 Nl/min |

| Machine Description | |

| Length x Width x Height Netto weight Noise Level | 1226 x 1140 x 940 mm 450 kg < 75 dB |

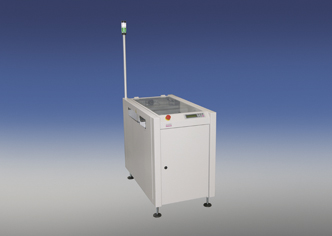

VEGO Dynamic LLE01 / Stacker with buffer for PCB packages

Available on backorder

The logistics unloader LLE 01 is used to unload marking stations with bare PCBs.

It combines a buffer station for PCB batches and a restacker station in one unit. The system is designed for correctly sorted stacking of the PCB batches according to the FIFO principle. The stacked PCBs are stored mechanically isolated from each other until removal. This prevents the possibility that individual circuit boards of various charges may be mixed up.

The PCB is taken over onto a conveyor and positioned. For stacking, the transport rails are retracting and the PCB falls onto the stack. After reaching the adjusted stack height, the PCB stack will be moved into the buffer. The stack is lifted up and then provided in the machine by batch for simple removal.

Features

Processing of the batches according to the FIFO principle

Capacitiy 6 batches of 60 mm

Unloading the machine without stopping production

PCB alignment before stacking

Stacking from the top

Electrical width adjust

Colour display with graphical user interface

Product parameters can be changed during running operation

Product memory function

2 colour signal lamp (LED) and alarm horn

Small footprint