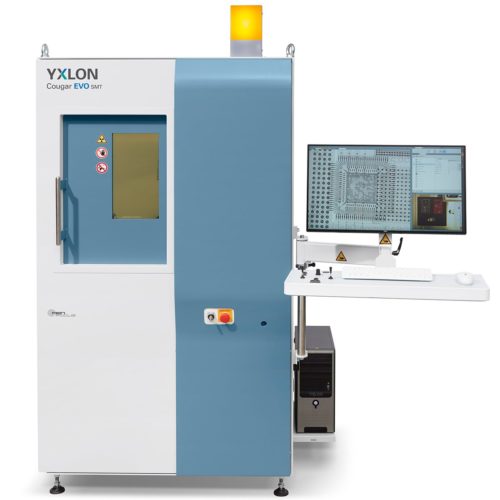

Today, mass-market electronics are manufactured almost exclusively on high-performance assembly machines. Time is literally money. Therefore, two aspects are of particular importance: maximum quantities and minimum changeover time. When it comes to the necessity of counting components before or after the assembly progress most manufacturers are still using the old fashioned approach of manual counting devices. VisiConsult, as a specialist for X-ray systems and automation, developed the XRHCount based on X-ray technology in order to speed up this time consuming process.

The cabinet has a footprint of 1.25m x 0.85m, a height of 2.2m and is certified by the German TÜV. Significant is that there is no X-ray leakage, an automatic drawer, automated label printing and an interface to all common warehouse management systems. The system is also designed to provide maximum safety and an ergonomic working position for the operator.

VisiConsult has certified representatives and service partners all around the world. This guarantees a very short response time for first level support in regional language. As the system is very easy to operate we include a supervisor training that entitles the customer to train their own operators. This makes the XRHCount very prone to employee fluctuation.

VisiConsult developed the first automated component estimation system that makes a prior type selection obsolete. This decreases the handling time and leads to robust counting results. The consequence is that even new types can be processed by the system if a similar type is already implemented in the type database. The system will just detect the similarity and automatically use the best match. In case of a completely new type a warning is shown and the reel can be submitted to the VisiConsult Counting Cloud. For detailed explanation please refer to the data sheet below.

Please Visit Manufacturers Website For More Information